XS Coated Cellophane Film in Reels at High Aromas Barrier

Transparent, Heat Sealable, XS Cellophane in Reels with High Barrier Properties to Oxigen and Aromas

Twistable Film for Wrapping of Candies, Chocolates, Sweets with High Speed Machines

Reels for the Flexible Packaging of Food used in Automatic Packaging Machines (Flowpack Machines, Horizontal – HFFS, Vertical – VFFS, Overwrapping Machines)

Cellophane (regenerated cellulose film) was invented in 1908 by Jacques Edwin Brandenberger, a Swiss chemical engineer.

Cellophane was the first transparent film launched in the market, and for this reason has taken the meaning of a common name. Even today alot of people usually calls cellophane all the transparent films. As a matter of fact now the range of transparent films is extremely huge, most of them comes from oil, and only a very small part is still made up of real cellophane.

Especially in the heat sealable version has given a decisive drive to the development of flexible packagings, leading at the invention and the improvement of automatic packaging machines, and with the creation of the flexible packaging industry.

Renewable Wood Pulp Resources

The raw material used for the manufacturing of cellophane has always been of vegetable and non-fossil origin. In fact cellophane is derived from cellulose, which is the most abundant of all renewable and sustainable raw materials, obtained from the trees. In addition now are used wood pulp sourced from managed plantations cultivated according to the most modern ecological criteria.

These features mean a reduced intake of new carbon dioxide into the atmosphere thanks to the short carbon cycle . Cellophane has a content of (new) bio-based carbon that can vary from 90% to 99% (procedure ASTM D6866, measured with the method of carbon 14).

High Barrier Properties to Oxygen and Aromas

The basic film, Cellophane P, (where P stands for Plain) has excellent barrier properties to oxygen, but as it is, is neither heat sealable nor impermeable to water vapour. Therefore it undergoes to a process called lacquering which gives both these characteristics. Lacquering consists in coating on one or on both sides special transparent paints (calls, precisely, lacquers). The same lacquers on both sides can be used, or differentiated lacquers (each on one side). Lacquering film is now a fairly common process in the flexible packaging industry. In early 900 it was not so and it took almost twenty years to invent it for cellophane. It was only in 1927, in fact, that the cellophane lacquering was developed and patented by DuPont.

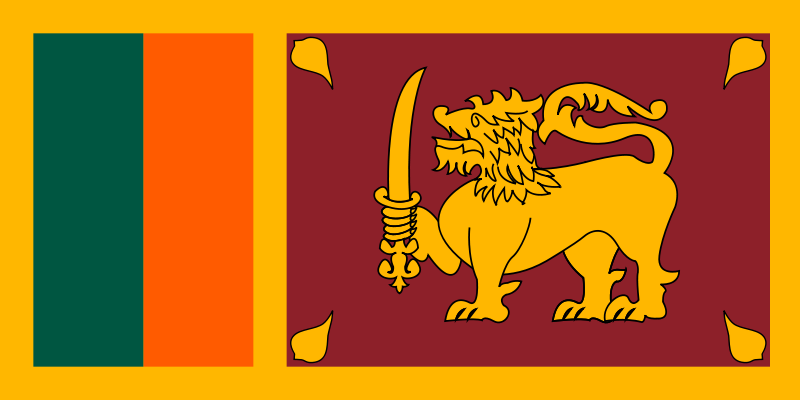

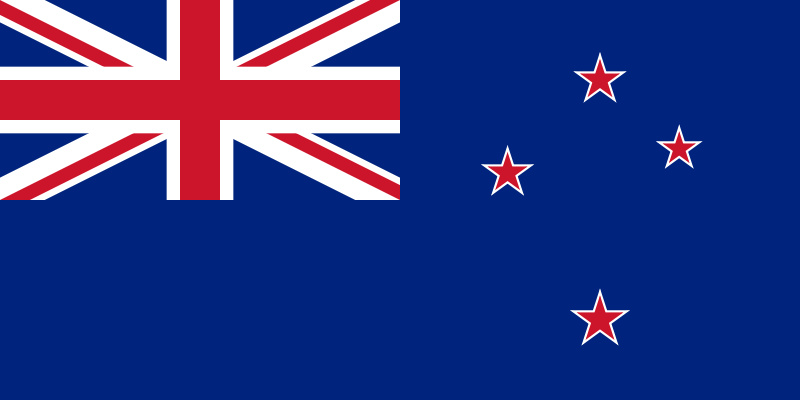

Today there are different types of lacquers which are applied to the basic film to get various types of films specialisied for different application requirements. You can get film completely waterproof or films with various degrees of controlled permeability that are used where the product should release with the time a certain degree of humidity. In Italy these films are not used that much, but, for example in France the semi-permeable cellophane is widely used to pack cheese, in the UK for meat pies.

Here it is offered the best heat sealable cellophane currently on the market, the XS type, produced in the EU. (The official name used in the European legislation is “regenerated cellulose film with coating“.) The XS abbreviation is used since a very long time and stands for Xaran coated, Sealing. This film is coated on both sides with lacquered PVdC. This lacquer gives the best barrier properties to water vapor, flavorings and gases, (in particular Cellophane XS has the best aromas barrier properties for pepper) increasing the shelf-life of food products.

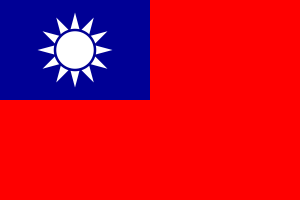

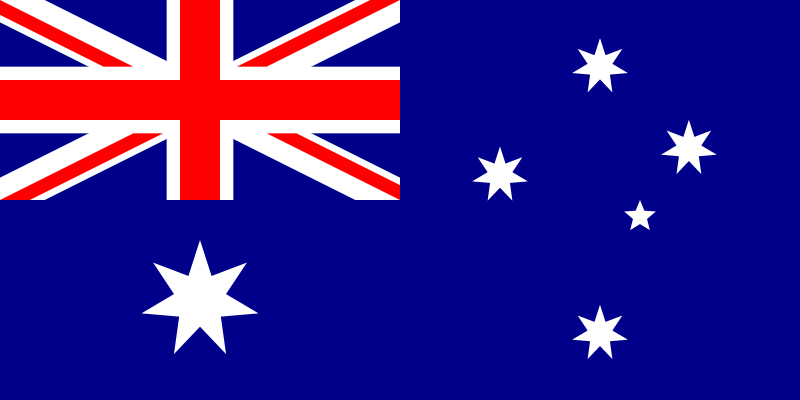

Film Produced in the European Union

For the production of films intended for contact with food our company uses only film produced in the EU by leading vendors that have been previously selected and appropriately accredited. This company policy gives the maximum guarantees in terms of compliance with regulations related to food contact (if you want to know the reasons for this statement we ask kindly to contact us, we will be happy to provide further details to support the claims).

Physical Characteristics of the Film

Cellophane has excellent mechanical characteristics and a limited elongation to breakage. Cellophane is resistant to oils and greases. It has a limited temperature shrinkage, and being a cellulosic film even if it is exposed to rather high temperatures, it does not melt but burns. It has excellent antistatic properties, this means that its surface does not attract atmospheric dust (as opposed to what happens to polypropylene) and therefore the packages made of cellophane last clean even if they are left exposed for a long time on the shelves of sale. Cellophane has excellent dead-fold characteristics (see below). Cellophane XS has an excellent appearance, both in terms of transparency (4.0% haze value at 2.5 °) and brightness (gloss value of 105 units at 105 °).

Cellophane XS has a very wide heat-sealing range (typically 100-160 ° C). This feature combined with a very pronounced smoothness allows the use of this film also on packaging machines with a limited temperature control system (old or very economical machines), or on the contrary, with very high speeds.

Film for Twisting

Cellophane keeps the twisting and this peculiarity can be successfully used on those items that have to keep the folding or the bow. Almost all the candies, chocolates and nougats have a wrapping with the bow or a double bow. Consumer is used to unwrap the candy pulling with two fingers the bows, it has become a gesture which is a prelude and foretaste of the sweet tasting itself. To do this type of wrapping special cellophaning machines are used, which have extremely high production speeds, and employ particular types of film which, subjected to twisting, keeps the twist (do not return to the original shape). Three films are currently available for this application: PVC, a particular type of polyester suitable for twisting, and Cellophane, which was the first film used for the purpose. All these three materials, in addition to transparent, offer also a white and a metallised film. Cellophane, in addition, has various versions of films colored in the mass, with very beautiful and eye-catching colours (red, blue, yellow, dark green).

Film for the Flexible Packaging of Food

Alternatively, cellophane XS is used on vertical automatic packaging machines (VFFS – Vertical Form Fill Seal Machine), horizontal (HFFS – Horizontal Form Fill Seal Machine), and in the over-wrapping (Over Wrapping Machine).

Cellophane XS offers excellent properties barrier to water vapor, oxygen and aromas (in particular is the best material to keep intact the aroma of pepper), is heat sealable on both sides (range 100-160° C).

Cellophane XS is suitable for contact with food as prescribed by the Italian law (Decreto Ministeriale 21.03.1973 and following amendations), as well as by EC Regulations n. 1935/2004, EC n. 2023/2006, and EC 2007/42 (and following amendations). Also legal requirements on labeling, upstream traceability and downstream traceability are satisfied. A specific statement to that effect will be issued on request.

Product Availability

The thickness available in house is 25,4 microns (other thicknesses are available upon request), the density about 1,44 g / cm3, the nominal unit weight is 36,5 grams per square meter, the nominal yield 27,4 square meters per kilogram.

Cellophane XS is supplied in reels. It is cut in the widths requested by the client (minimum cut 10 mm) and wound into disposable cardboard tubes. Standard reels have an inner diameter of the core of 70 millimetre (on request 76), the outside diameteer is 250 millimeters (greater on request). In standard diameters the weight of the reel is approximately 0.54 kilograms per centimeter of width. The length of the reel is about 1500 meters for the 25 micron film.

Cellophane XS is treated on the outer side (in the inner side upon request) for marking (for example in foods for printing the expiry date and the production lot). Each reel is individually wrapped to protect it from dust and is matched by a quality control sheet that identifies the exact batch of raw material used (traceability code) as well as the production phases. Indicative delivery time is 4 working weeks from the order date.

For any further information on films for flexible packagings, please don’t hesitate to contact us. Our commercial department is at your disposal you may need for any explanation, in-depth analysis, tests, new product or application development for films for flexible packagings.

Write, phone, fax or email at:

A. Peruzza srl – via Portelle 1 – 31010 Mareno di Piave – Tv – Italy

Telephone: int+ 39 0438 492335. Telefax: int+ 39 0438 492365.

Email: info@aperuzza.com

© 2011-2018 A.Peruzza s.r.l. is the sole owner or authorised user of the intellectual property rights relating to the information communicated herein. It is forbidden to copy, include in websites, distribute or anyhow publicize this document to third parties without prior written permission of the owner.